Creating highly reliable new structural materials

Using the microstructure and anisotropy of materials to achieve the inherent performance of materials is indispensable to improve the reliability and service life of structural materials and to effectively use limited resources. In this laboratory, deformation mechanism, microstructure control, and crystal orientation control are being investigated in processed bulk metals and alloys as well as deposited ceramics coating with a focus on the strength and fracture of materials, crystal plasticity, and metallography. Additionally, creating highly reliable new structural materials with long life and developing process technologies and evaluation methods for producing such materials are being conducted.

Research

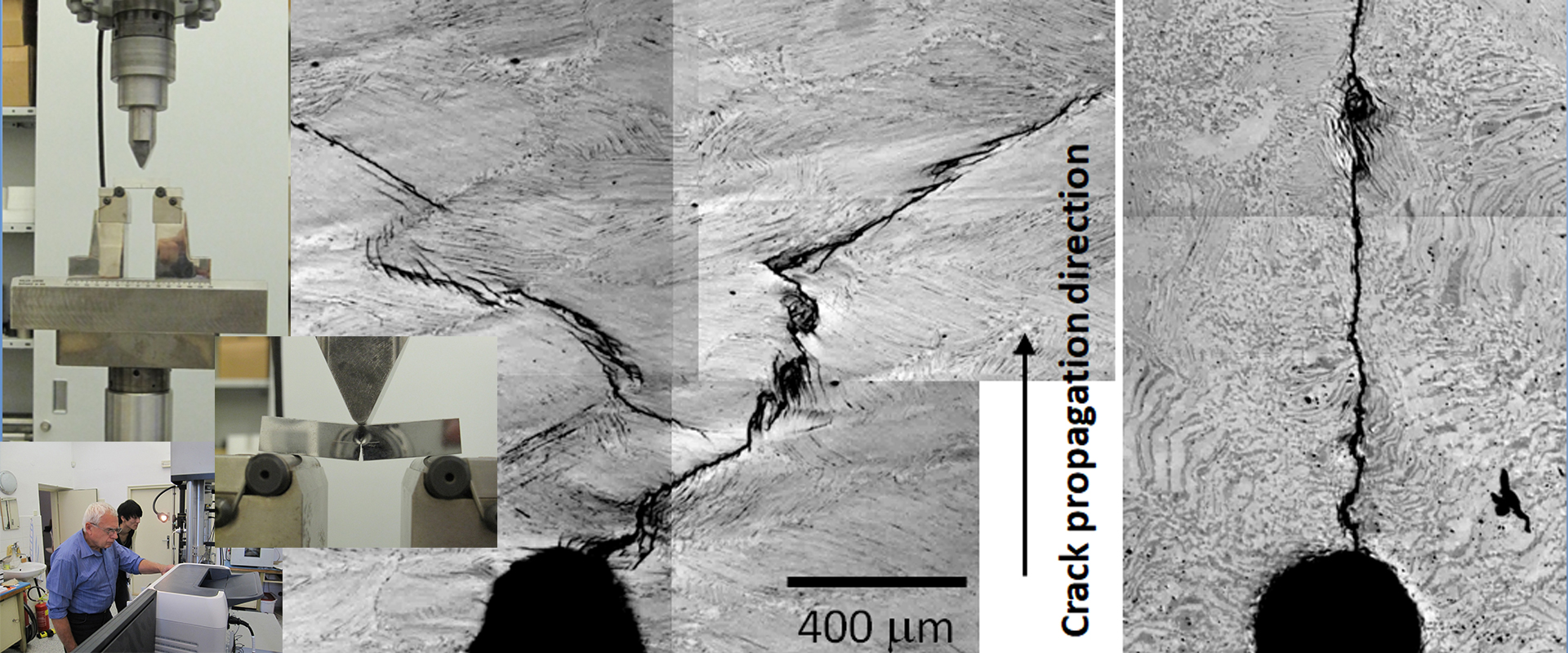

Research subject 1

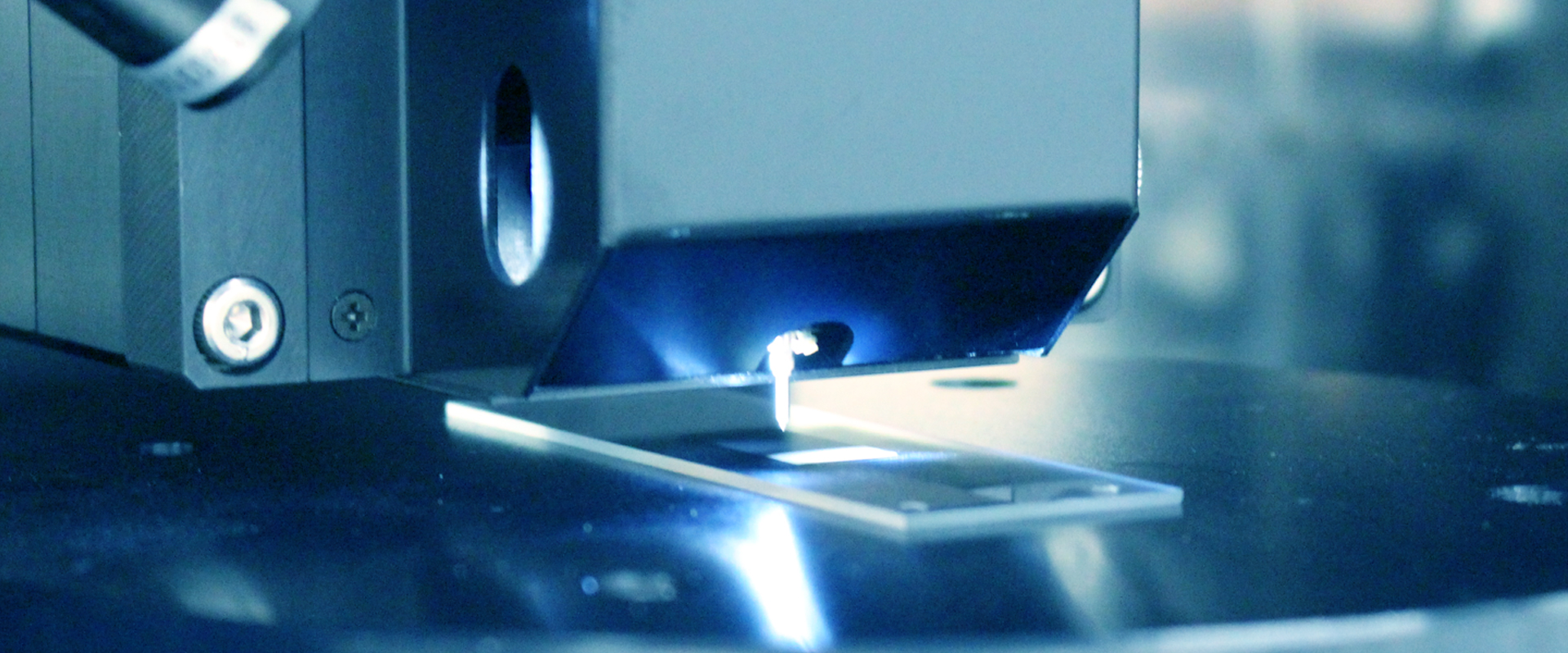

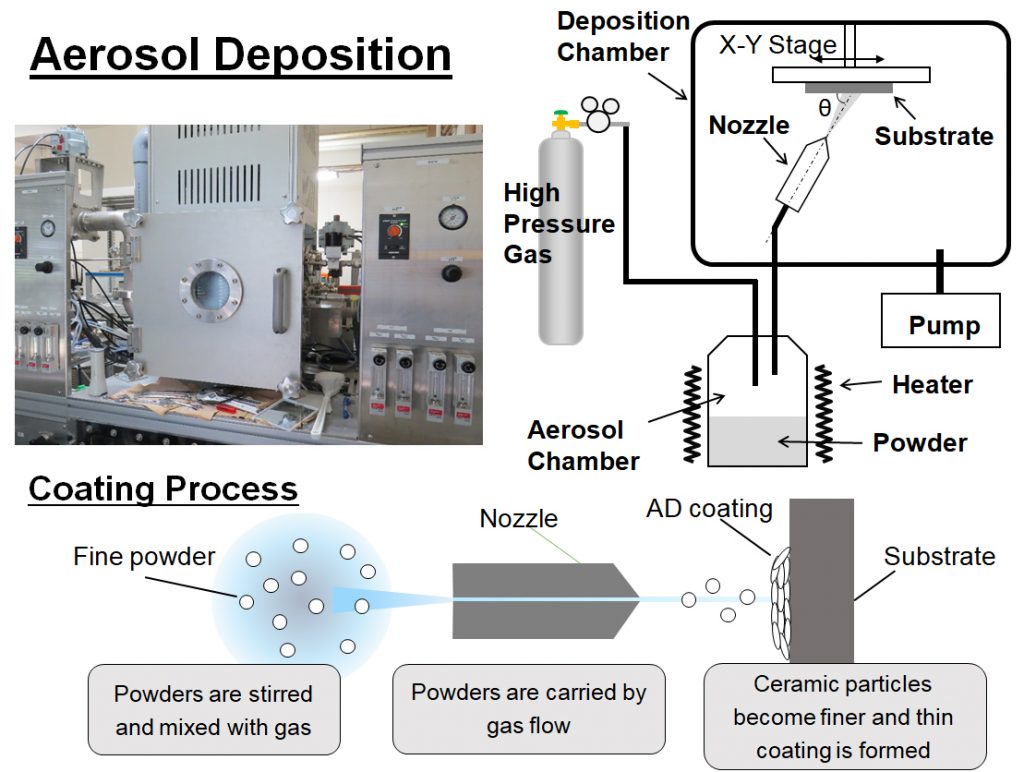

Formation of dense and crystalline ceramics coating by the collision of particles at room temperature

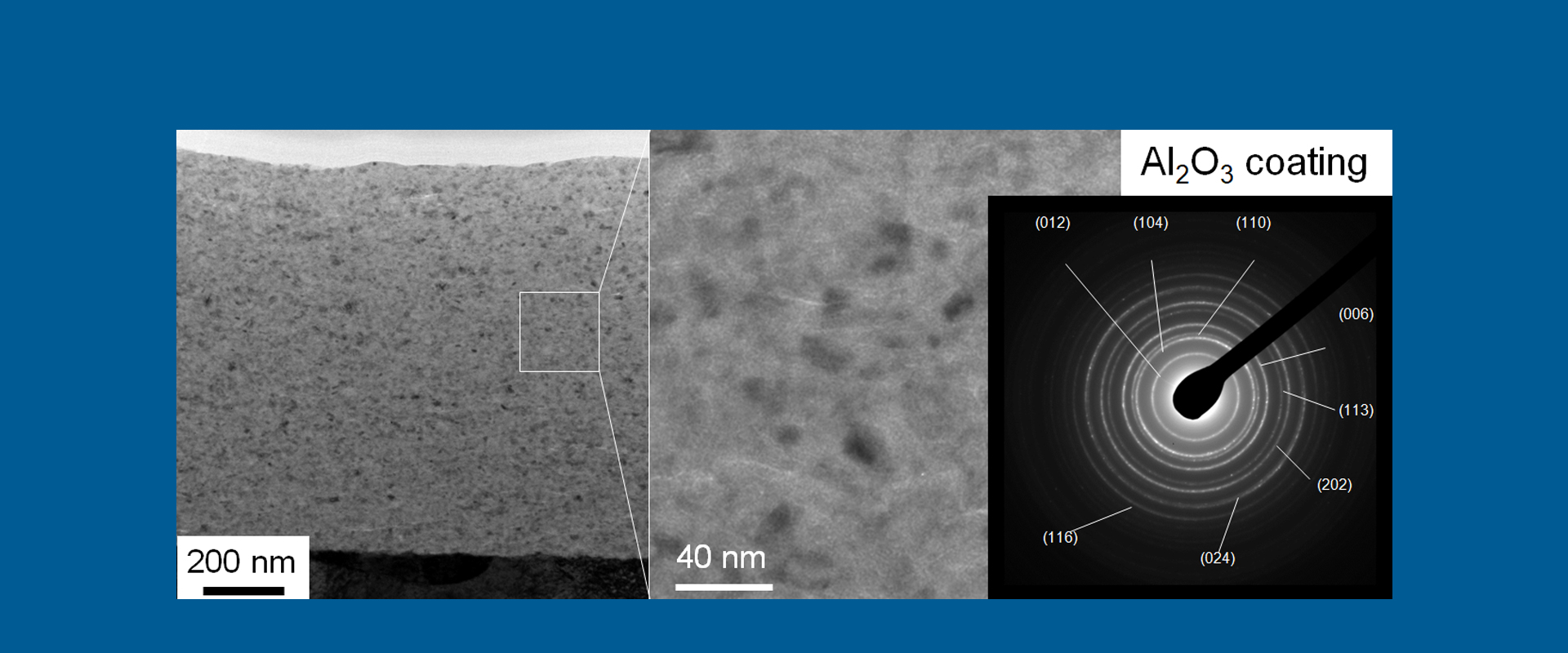

Research to improve the environmental resistance, heat resistance, wear resistance, and service life of structural materials such as heat resistant materials and tool steel by using ceramic coatings formed by the aerosol deposition (AD) method is being conducted. Additionally, new process technologies and evaluation methods for highly reliable materials are being developed.

Topics

- Development of environmental barrier coating for aircraft gas turbine engine by AD method and evaluation of delamination properties.

- Creation of ceramic hard film by AD method with consideration of repair of hard film for mold and evaluation of its mechanical properties.

- Development of ultra high temperature ceramic joint by collision of particles.

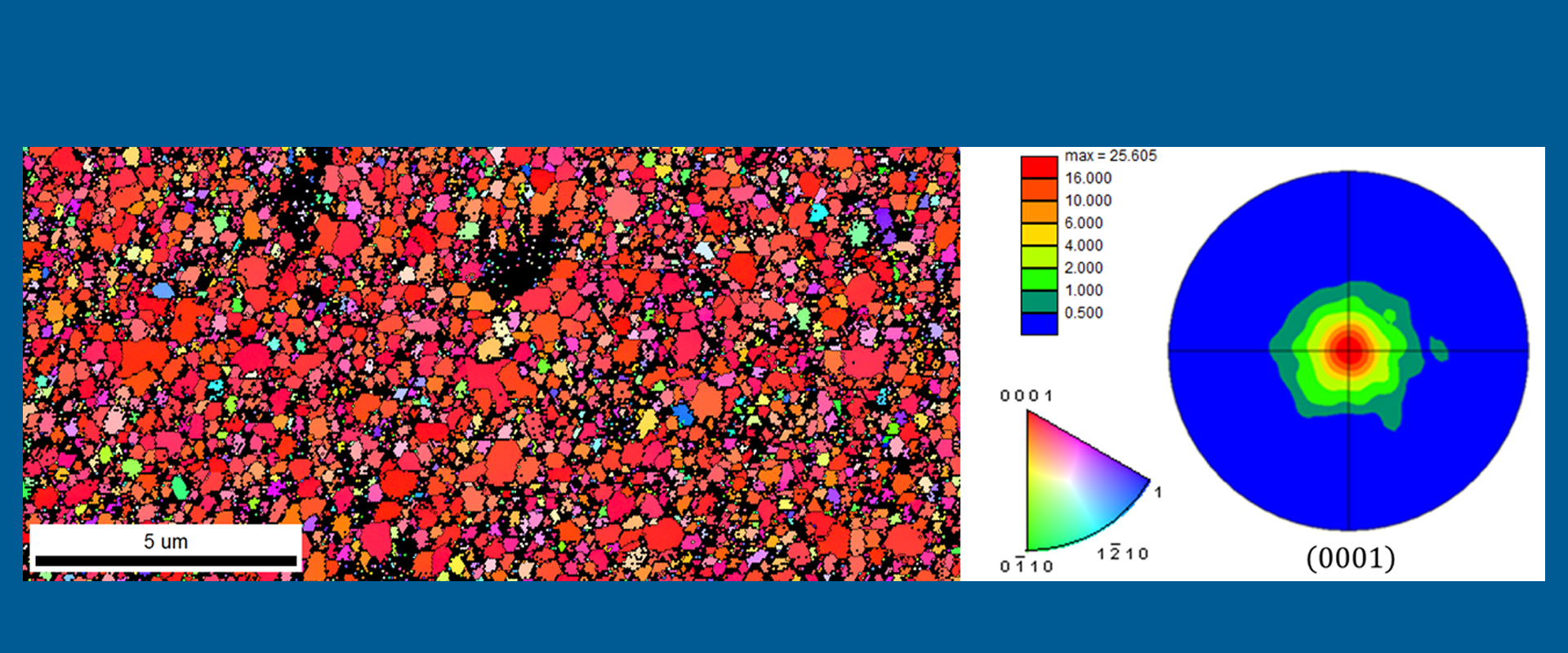

- Formation highly preferentially oriented ceramic coating processed by AD method.

The aerosol deposition (AD) method

The aerosol deposition (AD) method enables the formation of a dense and crystalline coating by spraying metal or ceramic powders onto the substrate at high speed at room temperature. Because the coating is formed at room temperature, deterioration of the substrate does not occur, and the composition of the powder becomes the composition of the coating without changing. Moreover, because oxidation of the coating does not occur during coating formation, forming non-oxide coating becomes simple. Furthermore, the possibility also exists of producing composite materials by mixing different powders followed by spraying. Because plastic deformation due to collision of particles with the substrate contributes to the formation of the coating, we recently discovered that the crystal orientation of the coating can be controlled by the AD method for not only metal particles but also for ceramic particles.

Research subject 2

Microstructure and texture (crystal orientation) control of materials by high temperature process, and room temperature process followed by heat treatment

We are working to achieve highly reliable and long service life structural materials with improved plastic workability, fracture resistance at room temperature, and high temperature strength by actively controlling their microstructure and texture using high temperature process, and room temperature process followed by heat treatment.

Topics

- Microstructure control and mechanical properties of Ti-Al-Nb based alloys during heat treatment.

- Microstructure and orientation control technology of Ti-Al-X based alloy by high temperature processing.

- High temperature deformation mechanism of MCrAlY medium entropy alloy.

- Microstructure and texture control of Mg-Li based alloy under uniaxial compression and plane strain compression deformation.

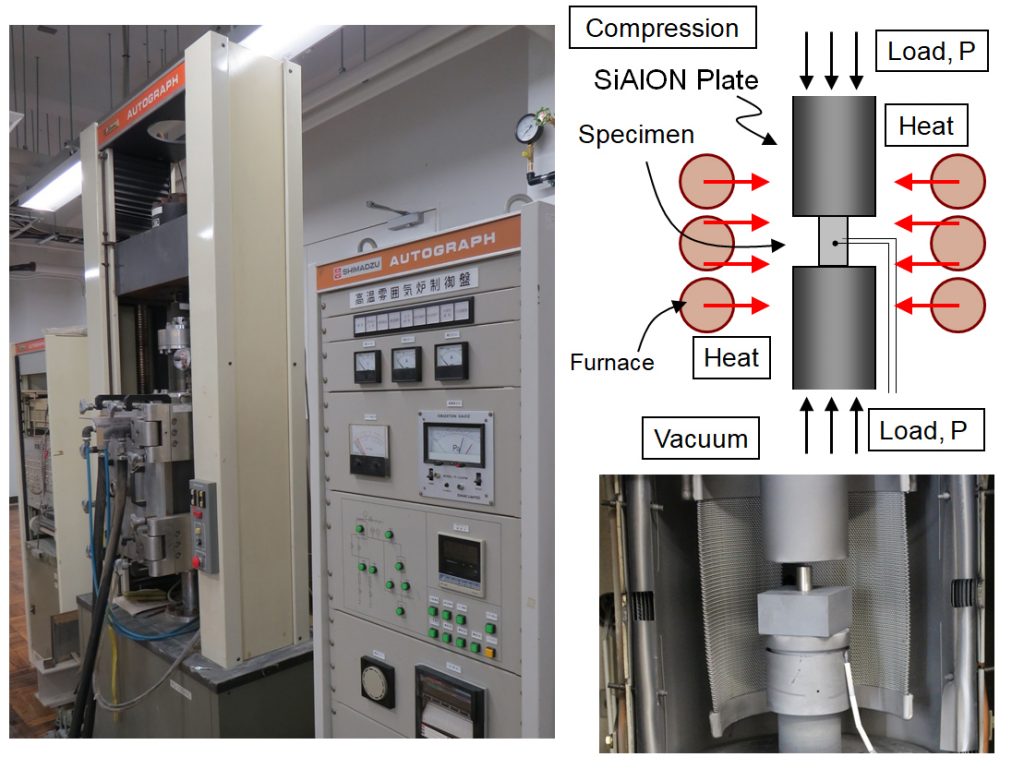

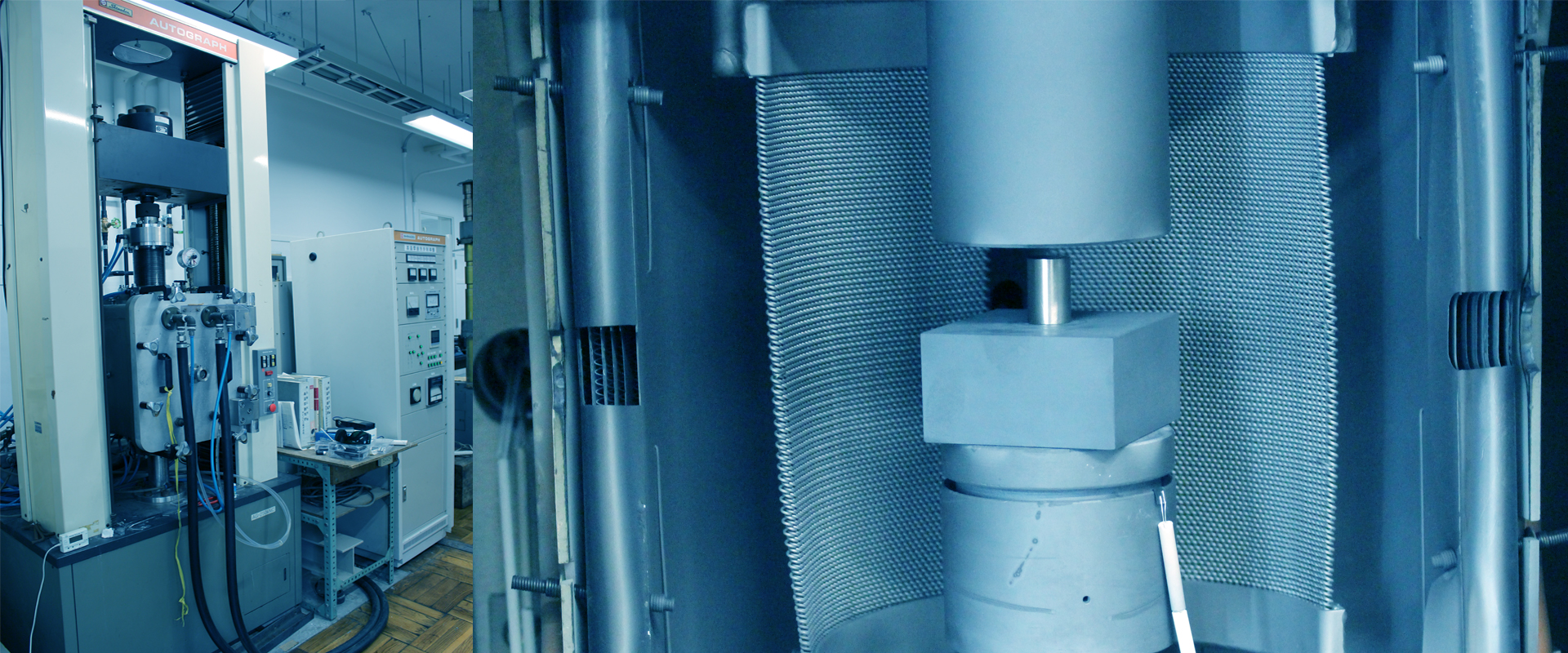

Thermo-mechanical processing of the test device

An electric furnace is attached to a universal testing machine and used as a thermo-mechanical processing test device. One of the two devices can process materials up to 900 °C in air. The other device has a capacity to process materials in a vacuum at the temperature over 1000 °C. Using a jig made of TZM alloy or SiAlON ceramic, uniaxial compression deformation, and shear deformation can be performed. Furthermore, plane strain compression deformation can be also performed which simulate hot rolling. Additionally, the possibility exists of conducting tests in which the true strain rate is constant.