Material Processing

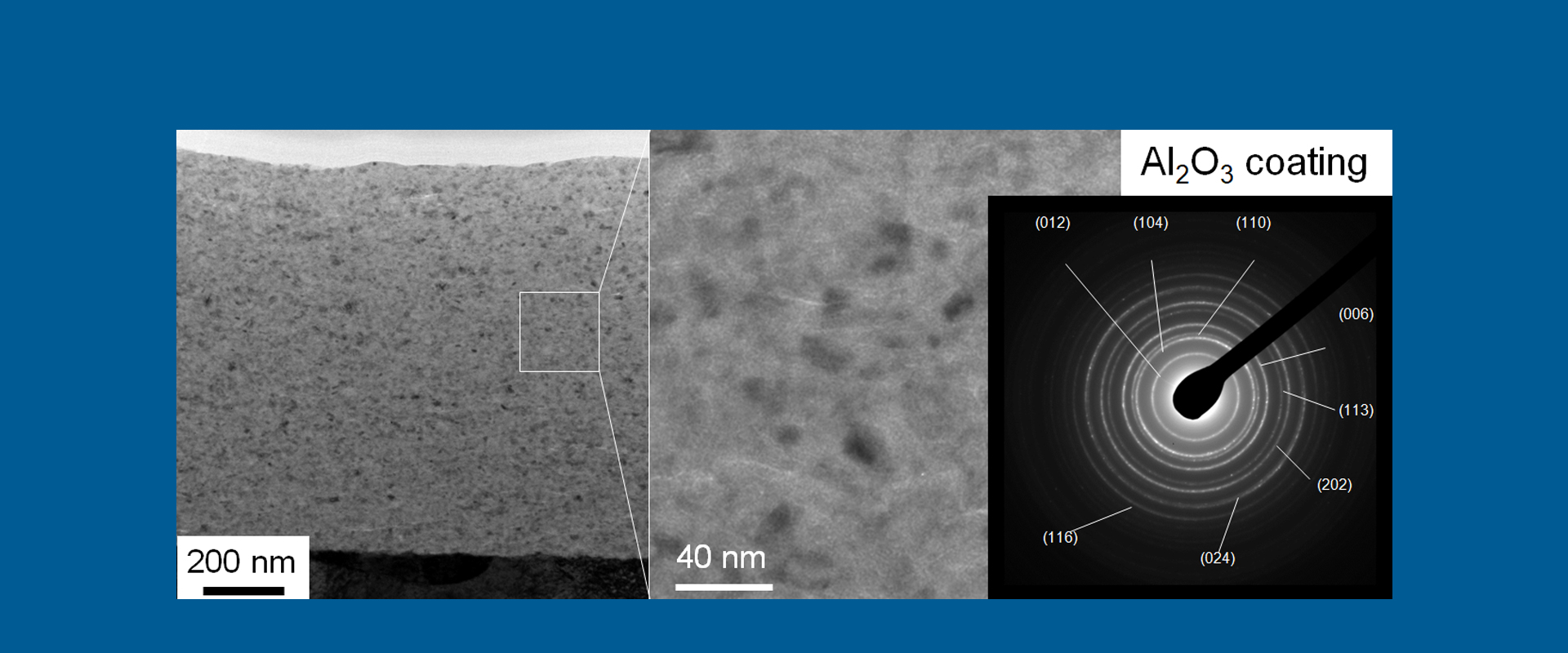

Aerosol Deposition Equipment

(Type GD-AE04/SS2 Mod., Fuchita Nano Technology)

A Dense and crystalline coating can be deposited by impacting fine ceramic or metal powders to the substrate at room temperature.

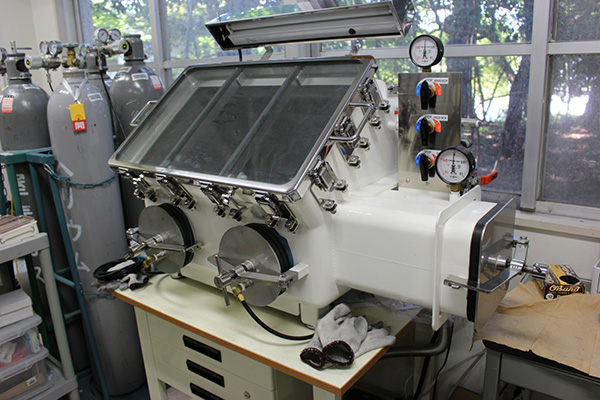

Vacuum Type Glovebox

(EZ-650L, UNICO Ltd.)

This is introduced to suppress the agglomeration of the powders which will be supplied for the aerosol deposition method. After drying the powders at the electric furnace, all the powders will be handled inside this box.

Planetary Ball Mill

(LP-1, Ito Seisakusho Co., Ltd.)

This is used in order to control the size of the powders which will be used for the aerosol deposition.

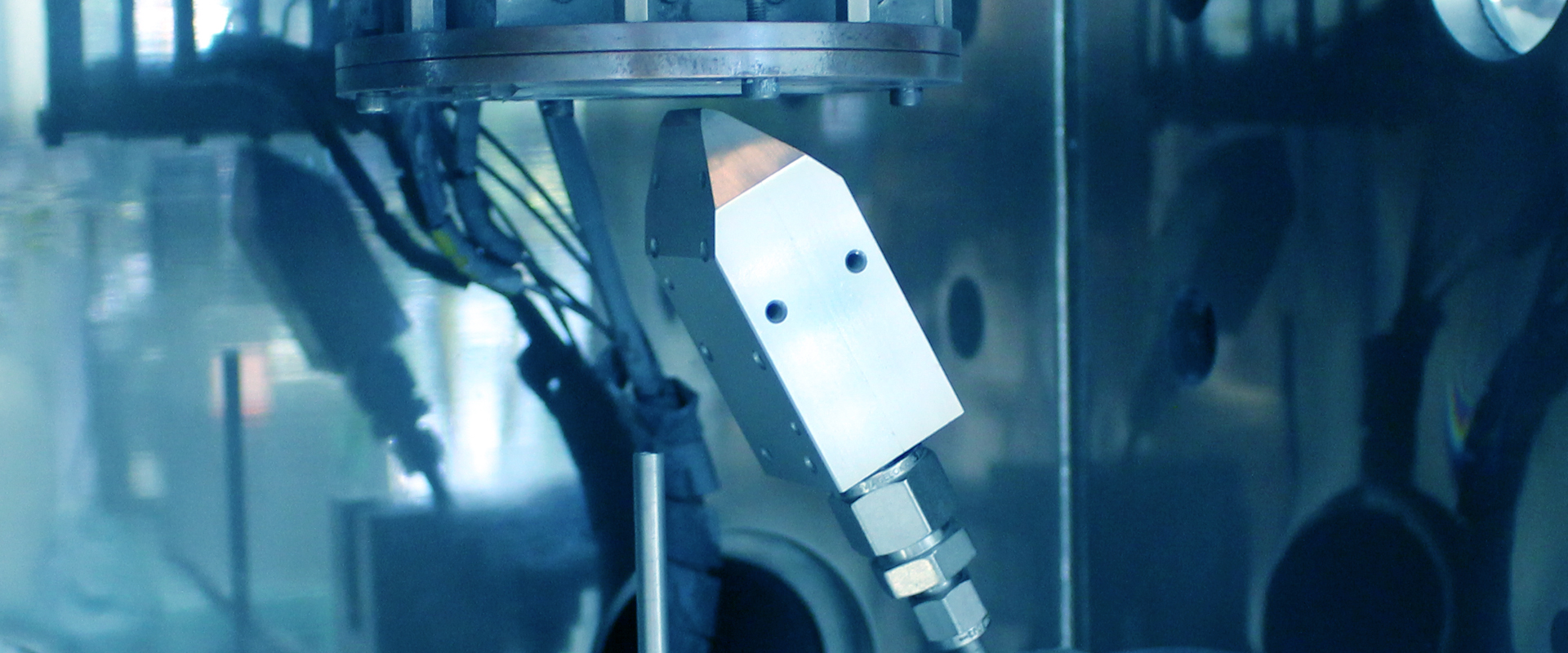

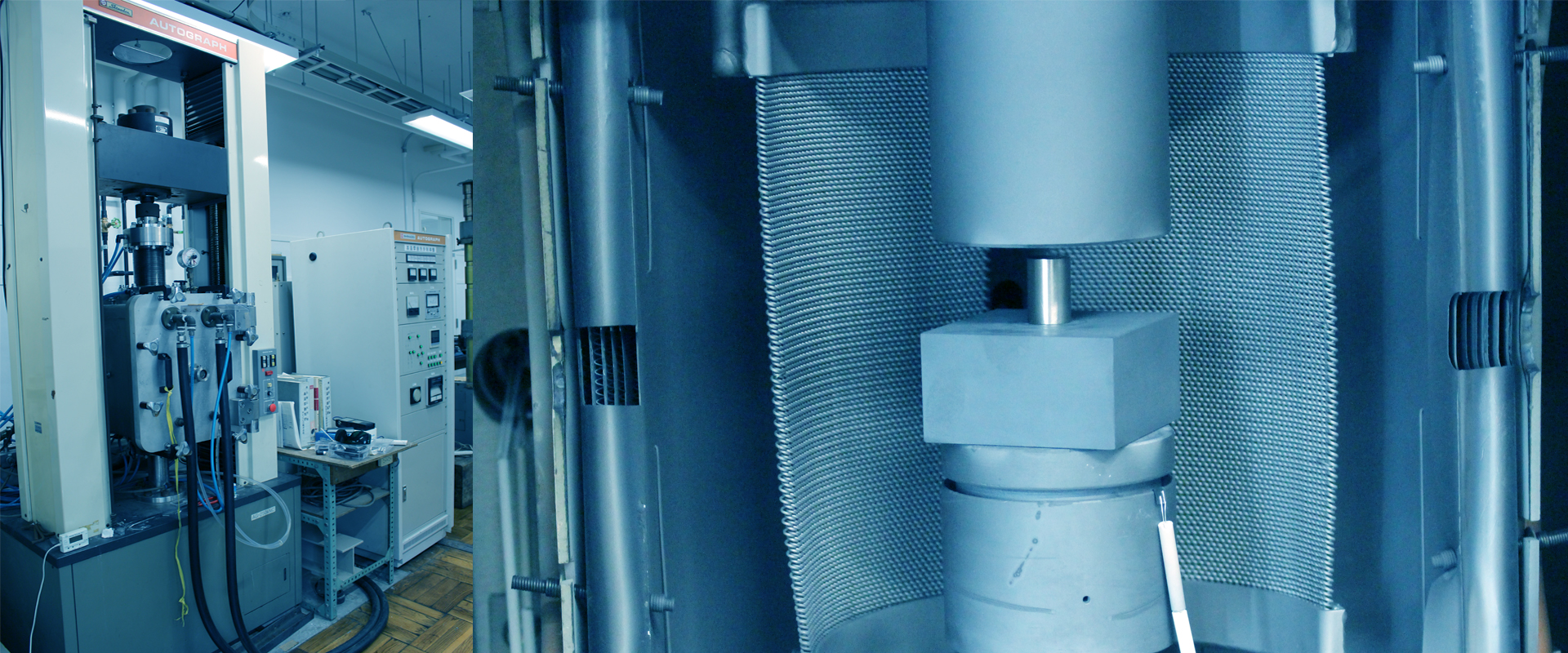

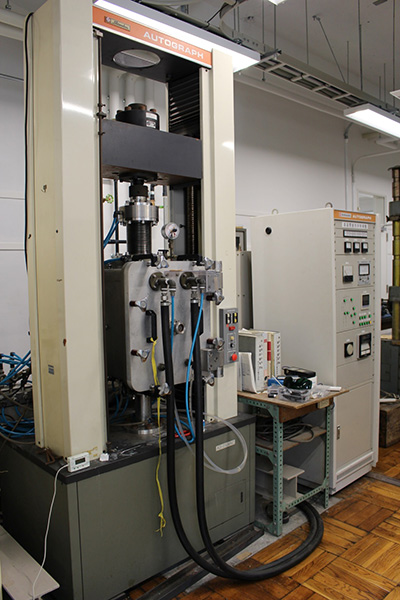

Thermo-mechanical processing equipment(assembled by Shimadzu Co. Ltd.)

Universal testing machine(AG-250kNC, Shimadzu Co. Ltd.)

Electric furnace(Tungsten mesh heater, NEMS Co., LTD.)

This is the equipment where the electric furnace which can heat the material up to 2000 ℃ in a vacuum was installed to the universal testing machine. This deform the metals at high temperature (up to 1500 ℃) in a vacuum. The rod used to deform the metals is made of TZM alloy.

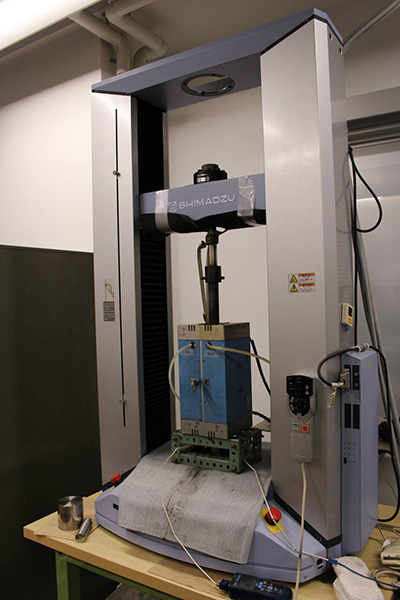

Thermo-mechanical processing equipment

Universal testing machine(AG-50kNXD, Shimadzu Co. Ltd.)

Electric furnace(Infrated furnace, Ulvac Co., Ltd.)

This is the equipment which can deform the material at high temperature (up to 1000 C) in an air. Depending on the temperature at which the material is processed, the rod can be replaced with stainless steel and nickel based superalloy.

Hot press / Vacuum heat treatment equipment

(PRESS-VAC-II, Tokyo Vacuum Co., Ltd.)

Electric furnace : Molybdenum heater

This equipment can apply a maximum load of 2 tons at a maximum temperature of 1300℃. This is used for the sintering and formation of jointed materials. It can also be used for heat treatment of materials in a vacuum.

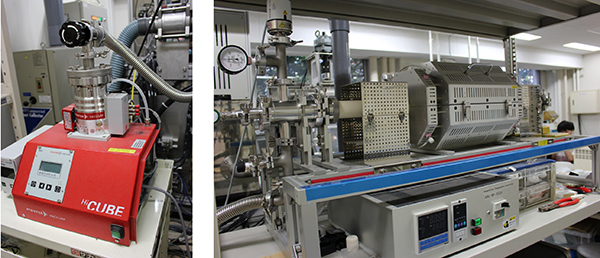

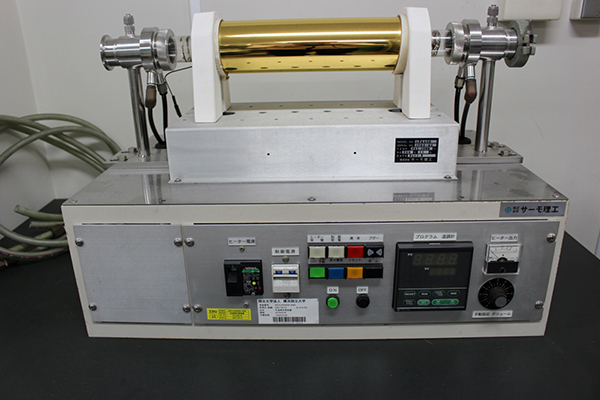

Heat treatment, Heat exposure

High temperature vacuum tube furnace (assembled by Heat-tech Co., Ltd.)

High temperature tube furnace(AHRF-50KC-9P, Asahi-rika Co., Ltd.)

Turbo pumping station (Hi Cube 80 Eco, PFEIFFER VACUUM)

This equipment is composed of high temperature tube furnace, alumina tube, vacuum gauge, vacuum piping and turbo pumping station. This furnace can be heated in a vacuum up to a maximum temperature of 1400℃. It is also possible to heat treat under inert gas condition.

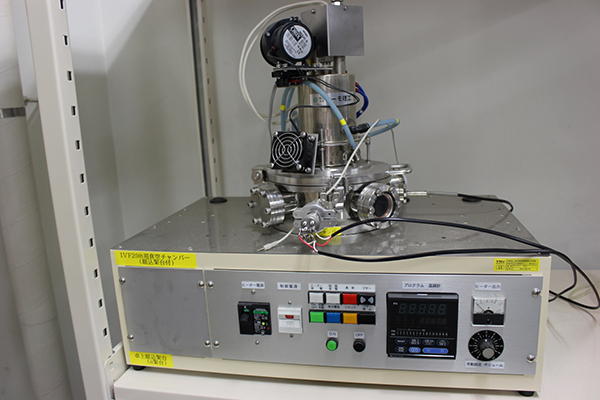

Focused irradiation type infrared vacuum furnace

(IVF298W, Thermo Riko Co., Ltd.)

This furnace is used for the heat treatment of the metal surface in a vacuum.

Uniform temperature heat treatment furnace

(GFA430VN, Thermo Riko Co., Ltd.)

This equipment can heat treat the material up to 900℃ in a vacuum and in an air.

Vacuum furnace

(FT-01VAC-50, Full-tech Furnace Co., Ltd.)

This furnace is used for the heat treatment of the bulk metal. It is also used in order to dry the powders. It is possible to introduce the inert gas to the furnace.

Muffle furnace

(EPTR-13K, Co., Ltd. Isuzu Seisakusho)

This furnace is used in order to dry the powders for the aerosol deposition. This is also used for the oxidation tests for high temperature materials and heat exposure tests for thermal barrier coatings.

Muffle furnace(assembled by Heat-tech Co., Ltd.)

Muffle furnace(AMF-20, Asahi-rika Co., Ltd.)

Temperature controller(AMF-N, Asahi-rika Co., Ltd.)

This furnace is used to dry the powders for film formation in aerosol deposition.

Natural convention oven

(DY300, Yamato Scientific Co., Ltd.)

A bottle for aerosolizing the powders is attached to the aerosol deposition equipment. This oven is used to dry the bottle.

Ultra high temperature box furnace

(KBF524N1, Koyo Thermo Systems Co., Ltd.)

Since MoSi2 heater is used in this furnace, it can be heated up to 1800 ℃ in the air. This furnace is used for the atmospheric heat exposure tests in ceramics and ceramics coatings as environmental barrier coatings.

Box furnace

(KBF894N1, Koyo Thermo Systems Co., Ltd.)

This furnace can be heated up to 1150℃ in the air. This is used for the heat treatment of the metals.

Electric furnace

(FT-101, Full-tech Furnace Co., Ltd)

This furnace can be heated up to 1200℃ in the air. This is used for the heat treatment of the metals. Oxidation tests for metals and heat exposure tests for the thermal barrier coatings are also applied to this furnace.

Mechanical processing and polishing

Precision cutter

(RCB-971, Refine Tec Ltd.)

This cutter is used for cutting the specimens.

Precision cutter

(Refine Tec Ltd.)

This cutter is used for cutting the specimens. This is old but has enough ability to cut the materials. Pipes and motor around the water was refreshed.

Low speed precision cutter

(MPC-130, Musashino-denshi Co., Ltd.)

This cutter is used for cutting the specimens which were formed by high temperature deformation. The specimens are slowly cut using a weight. Thus, the specimens can be cut without strain.

Grinder/polisher

(RPO-128K , Refine Tec Ltd.)

Automatic grinder/polisher

(AMO-210 , Refine Tec Ltd.)

These polishing machines are used for grinding and precision polishing of the surfaces and cross sections of the specimens. Manual polishing and polishing using automatic polishing equipment are possible.

Semi-automatic grinder/polisher

(MiniMet 1000, BUEHLER)

This polisher can perform automatic polishing with only one specimen. This single machine can do everything from rough grinding, precision polishing and final polishing.

Vibratory polisher

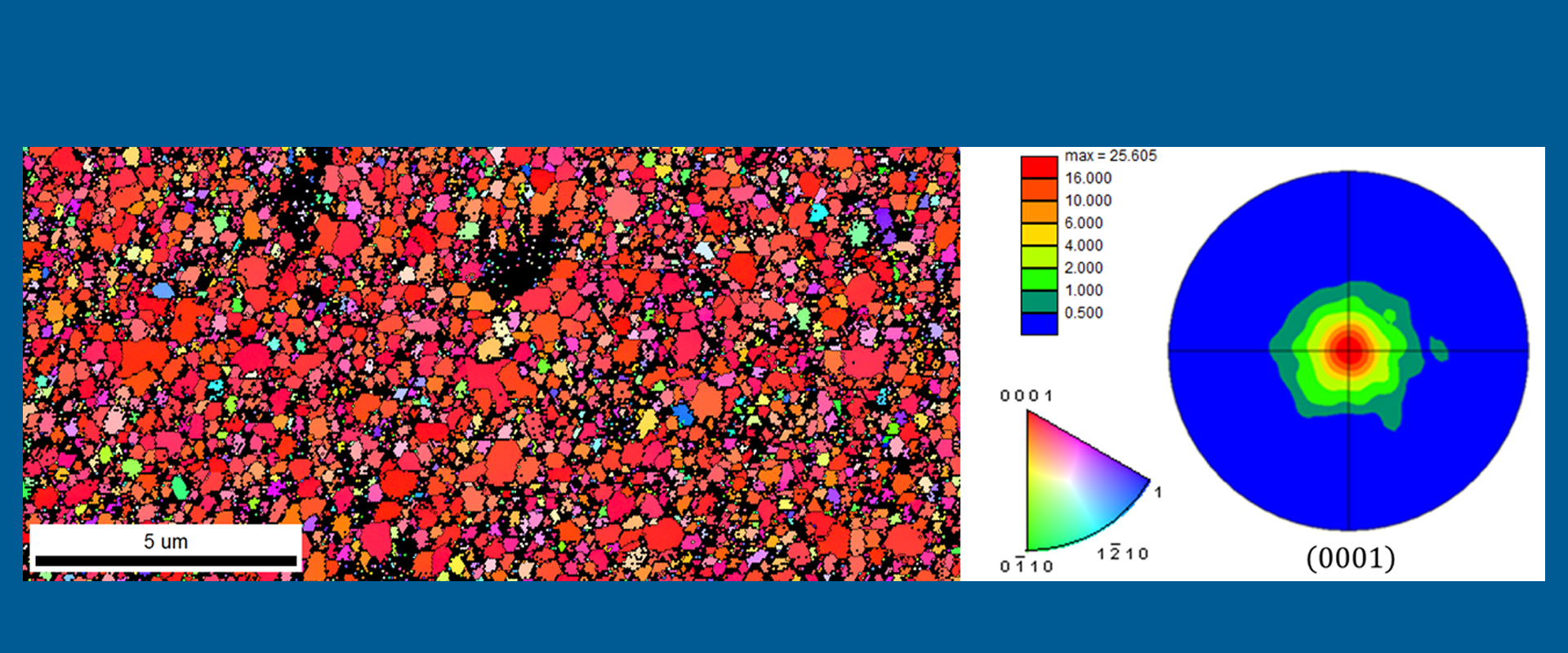

(VibroMet 2, BUEHLER)

This polisher is an automatic polishing machine dedicated to final finishing. Strain remaining on the surface after normal finish polishing can be removed. Therefore, it is indispensable for the specimens for EBSD measurement.

Ion milling system

(IM4000 plus, Hitachi High-Technologies Co.)

This equipment is used to finish the cross section of ceramics coatings processed by aerosol deposition.

Evaluation of mechanical and physical properties , microstructural observation

Tensilon universal testing machine

(RTF-1310, A&D Co., Ltd.)

This equipment can apply a load to the specimen up to 1 ton. Tensile tests, compressive tests, three point bending tests, and other tests in order to evaluate the mechanical properties are possible to undergo by using this equipment.

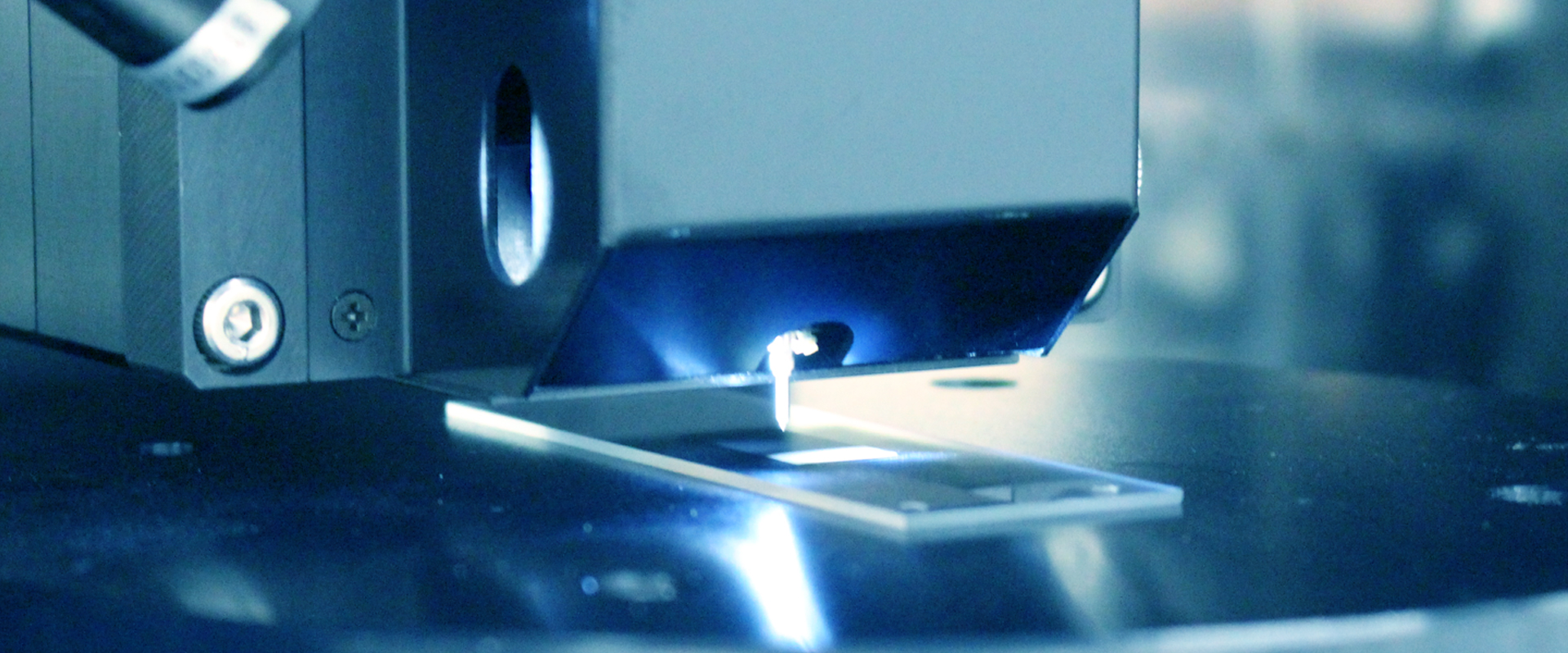

Dynamic ultra micro hardness tester

(DUH-211S, Shimadzu Co. Ltd.)

This testing machine was introduced to measure the hardness and elastic modulus of a ceramics coatings in a very small area. During the measurement, the surrounding environment is kept quiet. This is the tester which applies load and unload to a specimen with a small load. Therefore, vibration is strictly prohibited. During the measurement, the surrounding environment is kept quiet.

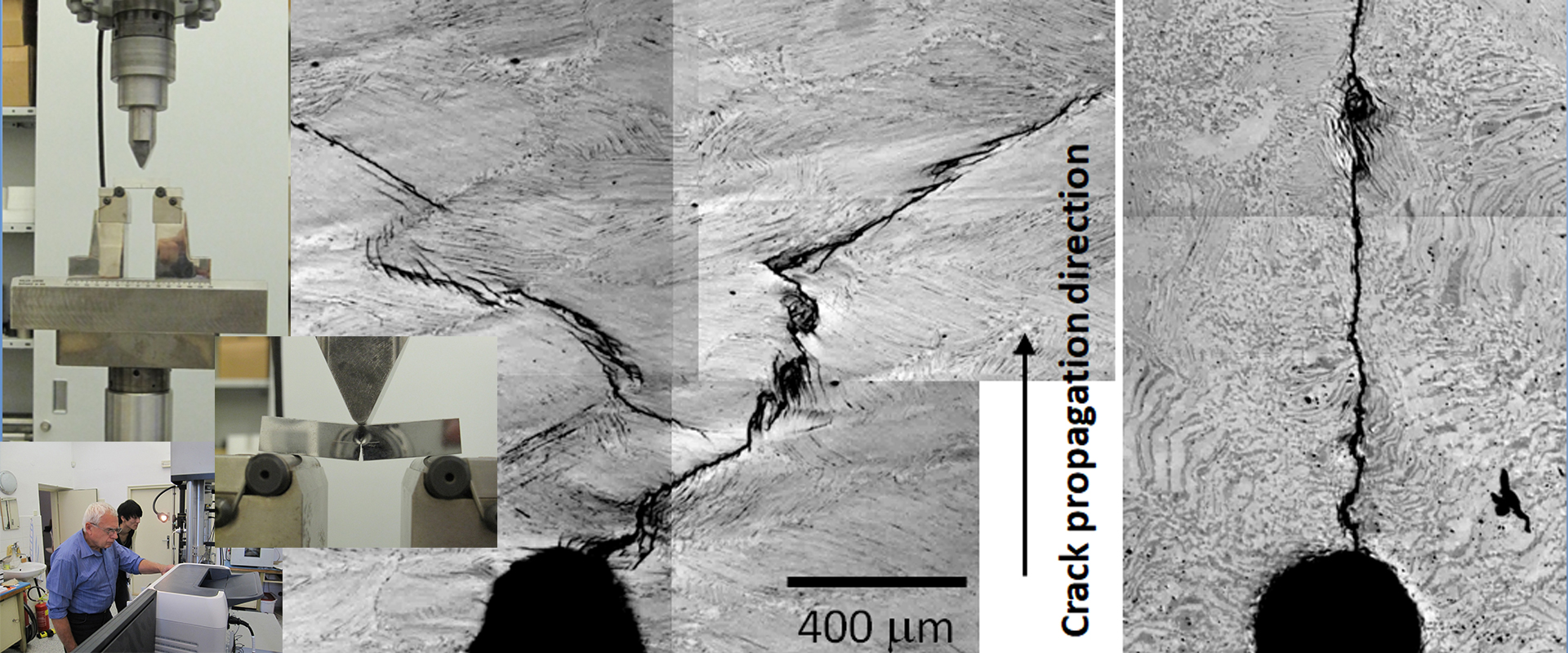

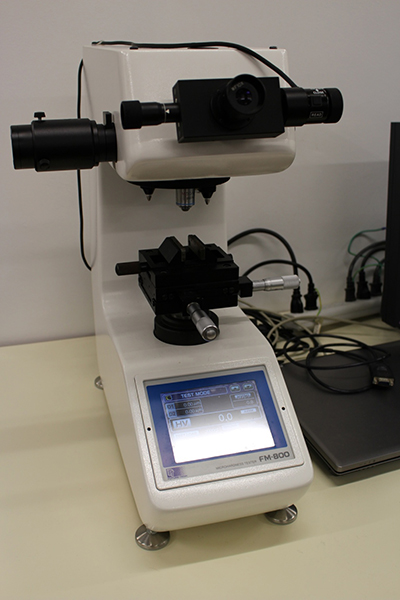

Microhardness tester

(FM-800D, Future-tech Corp.)

This tester can apply loads from 1 to 2000 gf to the specimen. This testing machine can measure both Vickers hardness and Knoop hardness. Measured data is imported to a personal computer. Since the indentation of the indenter to the ceramics surface generates cracks, introduction of pre-crack and observation of crack propagation are possible.

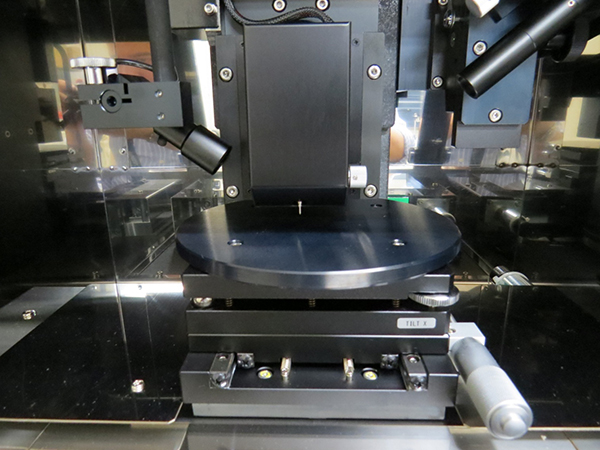

Microfigure measuring instrument

(ET-200, Kosaka laboratory Ltd.)

This equipment was introduced to measure the roughness of the ceramics coatings surface and the thickness of the coatings.

Differential thermal analyzer

(DTA-50 , Shimadzu Co. Ltd.)

This instrument is used for thermal analysis of metals (alloys).

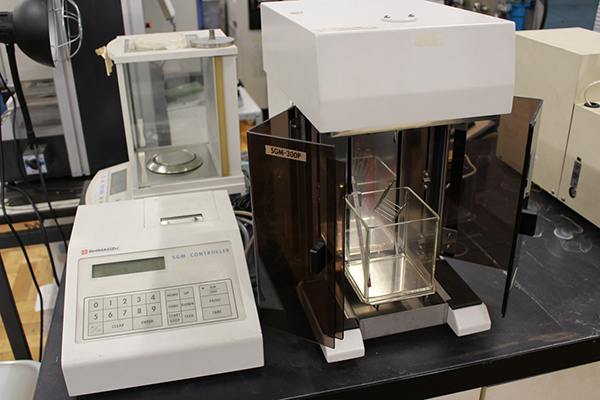

Specific gravity measuring device

(SGM-300P, Shimadzu Co. Ltd.)

This is used to measure the specific gravity of sintered bodies.

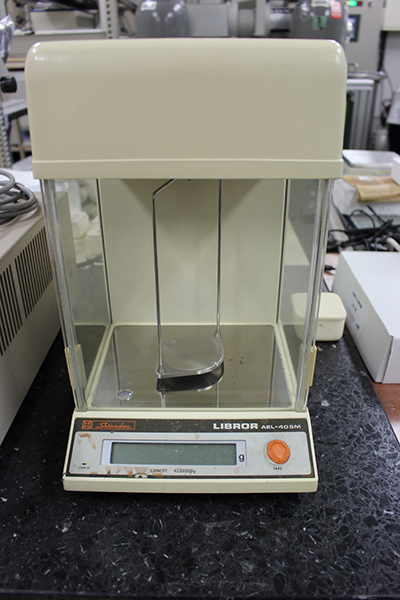

Balance

(AEL-40SM , Shimadzu Co. Ltd.)

This balance is used for measuring the weight of powders. It is also used to check the weight change of the specimens during the oxidation tests.

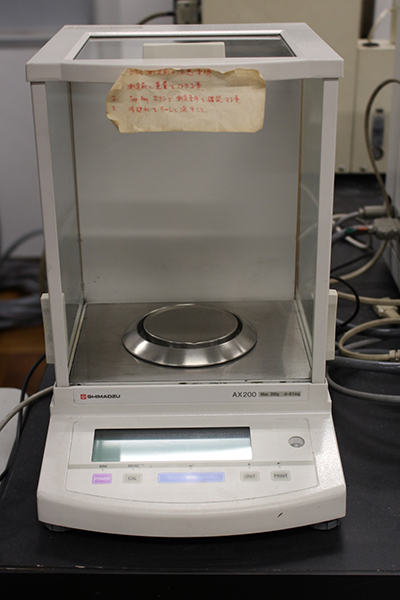

Balance

(AX200, Shimadzu Co. Ltd.)

This balance is used for measuring the weight of powders.

Scanning electron microscope

(JSM-5310, JEOL Ltd.)

This is used for specimen observation. Backscattered electron images are also possible to observe.

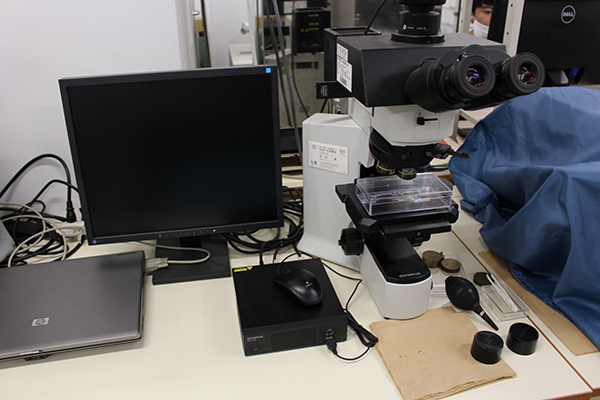

Upright microscope

(BX51M, Olympus Co.)

This microscope is used to observe the microstructure of metals.

Stereo microscope

(SZX7, Olympus Co.)

This microscope is used to observe the macroscopic view of the specimens. It is also used to check the status of the polished surfaces.